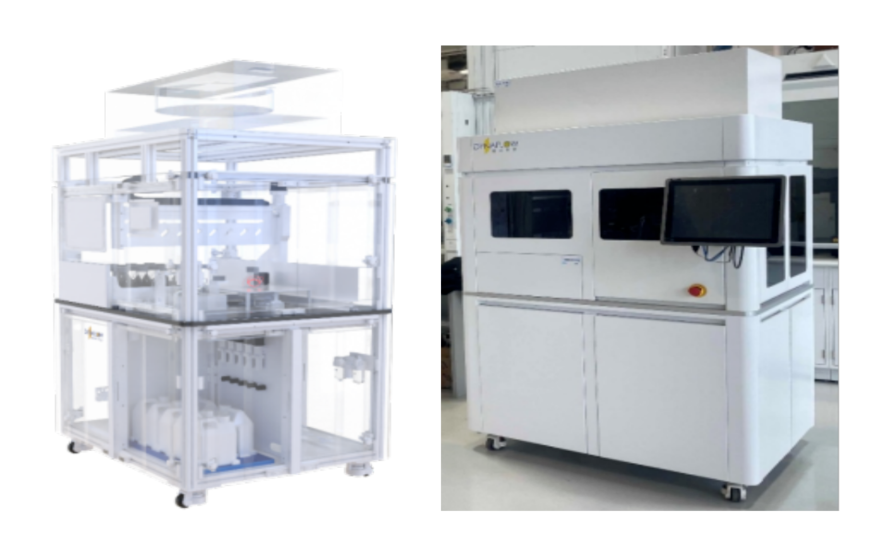

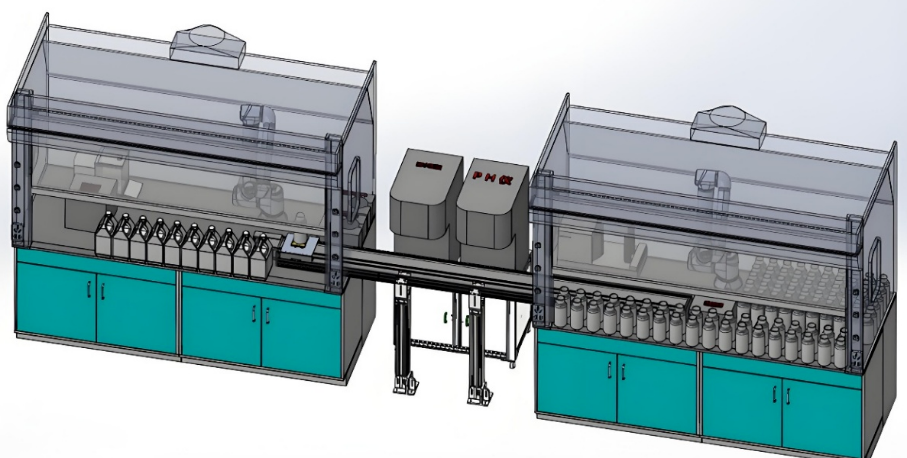

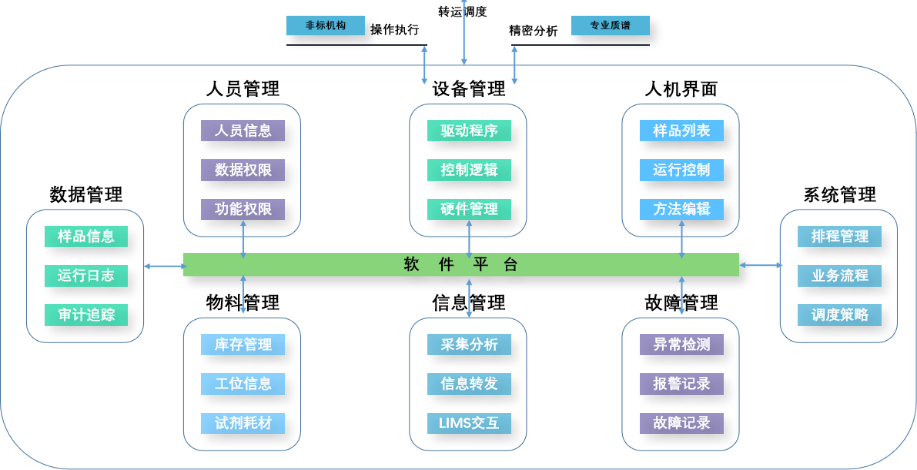

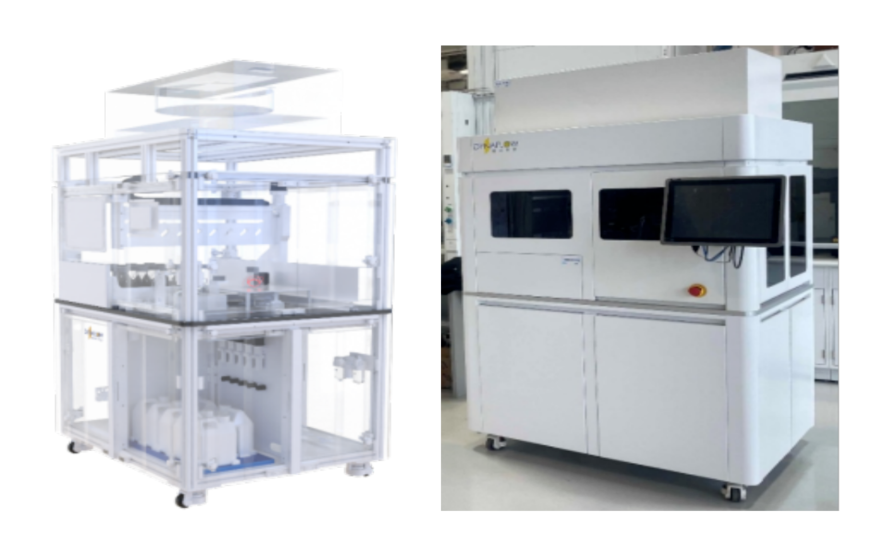

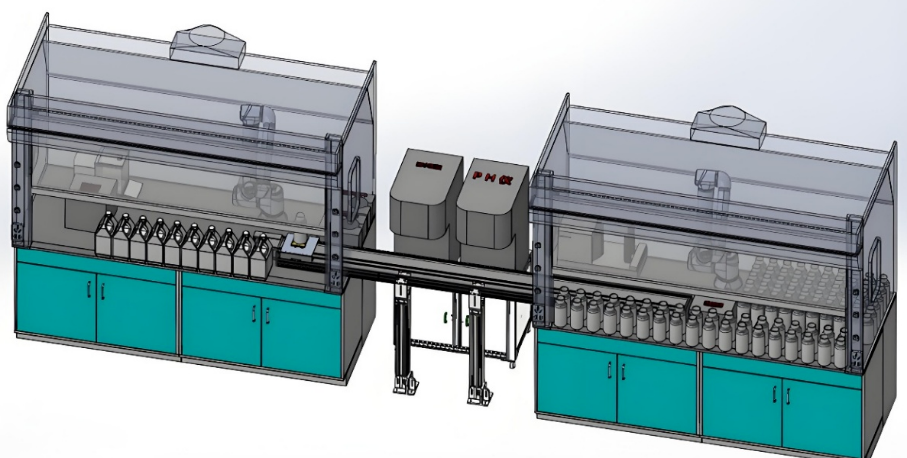

1. Dark Laboratory: The Smart Core of Mobile Phase Preparation

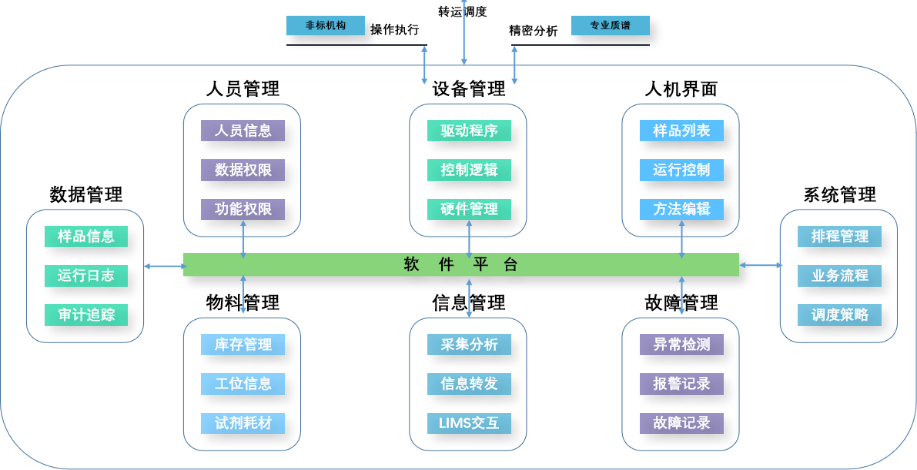

Green Upgrades By introducing a waste liquid recovery module, used mobile phases are purified and recycled, not only reducing environmental pressure but also achieving sustainable resource utilization.

1. Dark Laboratory: The Smart Core of Mobile Phase Preparation

Green Upgrades By introducing a waste liquid recovery module, used mobile phases are purified and recycled, not only reducing environmental pressure but also achieving sustainable resource utilization.